Triple Thermal Production

Independent thermal protection devices safeguard live wire, neutral wire, and platen temperature. This three-point system prevents overheating and ensures stable performance.

Maximise output with the HeatriX T+ – a powerful electric twin-station heat press with shuttle design. Featuring dual 40×50cm platens, auto-open function, and smooth electric drive, it’s built for speed, safety, and high-volume production.

Enquire Today

The HeatriX T+ is built for serious throughput, with an electric drive, twin shuttle stations, and auto-open operation for rapid, repeatable cycles.

Dual 40 × 50 cm platens let one operator load on one side while the other side presses, which reduces idle time and keeps production moving.

A digital LCD touchscreen controller delivers precise temperature and multi-timer control, so you can match settings to DTF transfers, HTV, sublimation blanks, and more.

The shuttle workflow improves ergonomics and safety, hands stay clear of heat, accuracy improves, and teams get consistent results across long runs.

Twin-station shuttle productivity, whisper-quiet electric drive, and certified safety — engineered for rapid, repeatable heat transfers with less operator fatigue.

Cover your core work with a single platform. T+ confidently handles DTF, HTV/vinyl, sublimation, laser transfer papers, and rhinestone jobs — delivering high output and low cost per print.

Patent electronic technology runs quietly and consistently, applying digitally set, even pressure up to 400 g/cm² without the cost, noise, or maintenance of compressed air.

Built with qualified electrical components and certified to CE and UKCA standards. Expect dependable uptime and safer day-to-day operation for your team.

Tool-less, interchangeable platens (sold separately) let you move from tees to sleeves, pockets, labels, or awkward shapes in seconds — perfect for shuttle workflows.

The HeatriX T+ Twin Station is engineered for high-volume production, with dual shuttle platens, advanced safety controls, and rock-solid heat performance. Every detail is built to improve speed, consistency, and operator confidence.

Independent thermal protection devices safeguard live wire, neutral wire, and platen temperature. This three-point system prevents overheating and ensures stable performance.

The quick-change base system lets you swap platens in seconds, while the threadable design allows garments to rotate freely for faster, more precise placement.

Super-precise AT700 LCD controller provides accurate temp and pressure settings, multiple modes, and a 120-minute standby function for energy savings and safety.

The electric dual-station design allows one platen to press while the other is loaded or unloaded, keeping production flowing without downtime.

A removable control module makes servicing faster and simpler, helping reduce downtime and keep production schedules on track.

A large-format 40 × 50 cm platen provides plenty of space for oversized garments, panels, or specialty blanks with even heating across the surface.

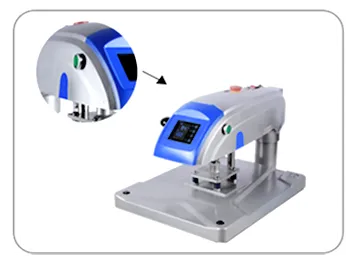

The protective cap shields operators from accidental scalding, boosting workplace safety during fast-paced production.

Reinforced spring system balances pressure across the platen, ensuring consistent transfers and crisp results with every press.

Handles substrates up to 50 mm thick, so you can confidently press bulky items while maintaining even heat and pressure distribution.

When you choose the HeatriX T+ Twin Station Heat Press, you also get Pozitive’s expert advice, setup resources, and dedicated local support — giving you confidence to run high-volume production smoothly.

Our team helps match your production needs with the right platen options, accessories, and workflow setups for maximum efficiency.

Access quick-start guides, wiring diagrams, and operating documentation tailored to the T+ so your team can get pressing fast.

Guidance on pressure, temperature, and timing for a wide range of substrates, plus workflow strategies for dual-station production.

Our Australian-based service team is available for troubleshooting, parts, and advice — including installation support via trusted partners.

Key specifications for the HeatriX T+ Twin Station Electric Heat Press — engineered for high-volume, precise and consistent heat transfers.

| Heat Press Style | Electric |

| Motion Available | Swing-away / Auto-open |

| Heat Platen Size | 40 × 50 cm (16 × 20 in) |

| Voltage | 110 V or 220 V |

| Power | 1800 – 2200 W |

| Controller | Screen-touch LCD Panel |

| Max. Temperature | 450 °F / 232 °C |

| Timer Range | 0 – 999 seconds |

| Machine Dimensions (W × D × H) | 94.7 × 72.5 × 71.7 cm |

| Machine Weight | 125 kg |

| Shipping Dimensions (W × D × H) | 110 × 83 × 87 cm |

| Shipping Weight | 140 kg |

| Certifications | CE / RoHS compliant |

| Warranty | 1 year full warranty |

| Support | Lifetime technical support |

The HeatriX T+ Twin Station Electric Heat Press is built for high-volume production. With dual 40 × 50 cm platens, auto-open swing-away motion, and precise LCD control, it maximises throughput while ensuring safe, consistent results. Backed by Pozitive support, you’ll receive expert advice, setup resources, and ongoing local assistance. Use the form below to request pricing, schedule a demo, or connect with our specialists.

| Item | Price | Qty | Total | |

|---|---|---|---|---|

| Subtotal |

$0.00 |

|||

| Shipping | ||||

| Total | ||||