Mimaki Print and Cut Machines

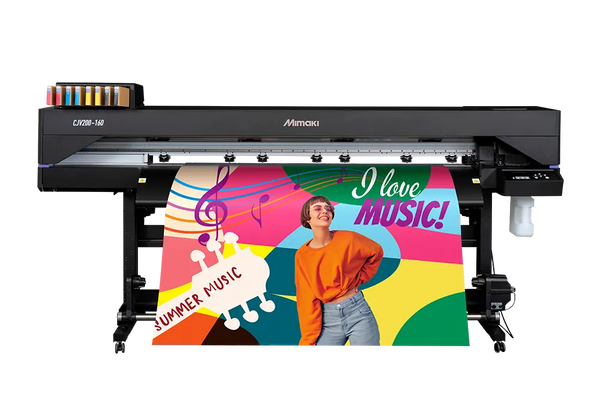

If you’re after a solution that delivers exceptional colour output and precision cutting in one efficient workflow, a Mimaki print and cut machine is the ideal choice. With a reputation built on reliable engineering and high-end performance, Mimaki systems are trusted by print professionals worldwide to produce vibrant signage, detailed labels and durable packaging with ease.

Explore Mimaki Print and Cut Machines

Read more

Why Choose a Mimaki Print and Cut Machine?

Mimaki’s technology stands out for its smart design, consistent quality and time-saving features. Their print and cut machines offer an integrated setup that eliminates the need for separate equipment, streamlining your entire production process.

Here’s what makes a Mimaki print and cut machine a worthwhile investment:

- Advanced Japanese engineering ensures reliable performance and long-term durability

- Auto-registration and alignment systems deliver clean, accurate contour cuts every time

- Ink flexibility, with support for both eco-solvent and UV options to suit different applications

- RIP software integration for seamless workflow management and faster job setup

Where a Mimaki Machine Excels

Mimaki systems are versatile enough to handle a wide range of media and applications. They are especially popular in industries like retail, events, packaging, education and manufacturing.

You can use a Mimaki print and cut machine to create:

- Vehicle wraps and window graphics with bold colours and tight contour cuts

- Custom labels and stickers ideal for branding, packaging, or promotional use

- Indoor and outdoor signage, including banners and floor graphics that withstand the elements

- Point of sale displays and prototypes, printed and cut in-house for quicker turnarounds

If you need more dedicated cutting capability, explore our roll to roll cutters, flatbed cutters, or a digital die-cutting machine for advanced short-run packaging work.

Best Mimaki Print and Cut Machines from Pozitive

We stock a selection of the most trusted Mimaki print and cut systems available in Australia, with models to suit every stage of your business journey.

A feature-rich eco-solvent system built for fast, high-resolution output. Ideal for larger businesses that need speed, accuracy and long-run reliability. With enhanced colour saturation and powerful cutting performance, it’s a strong all-rounder.

Combining UV-curable printing and integrated cutting, this model produces instantly dry prints with vibrant layered effects. Perfect for window graphics, backlit film and other premium applications.

A great choice for smaller or mid-sized operations looking for versatility and ease of use. With flexible media handling and cost-effective operation, it delivers professional results without the complexity.

If you’re unsure which model fits your workflow, our team is always happy to help you compare specs, output capabilities and pricing.

Keeping Your Mimaki in Top Condition

To get the best performance from your Mimaki system, regular upkeep is key. With a few easy routines, you can keep your machine running reliably and maintain the sharp quality your clients expect.

- Replace cutting blades as they wear to maintain clean, precise edges

- Run nozzle checks to avoid streaks and ensure consistent ink delivery

- Calibrate cutting alignment to prevent registration drift, especially on longer jobs

- Install firmware and software updates to access the latest features and performance tweaks

We’re always on hand with advice, technical support and spare parts to help keep your setup in excellent working order.

FAQs

What ink types do Mimaki print and cut machines support?

Most models support eco-solvent or UV inks, depending on the series. This gives you flexibility in terms of drying time, durability and media compatibility.

How accurate is the cutting functionality?

Thanks to Mimaki’s advanced registration systems, cutting is highly precise, even on intricate shapes or small decals.

Are Mimaki machines suitable for textile or backlit film printing?

Yes, several models can print effectively on backlit films. For textiles, media compatibility depends on the specific ink and fabric being used. Speak to us for tailored advice.

What are the running costs like?

Mimaki machines are designed for efficiency. Ink usage and media waste are both minimal with proper maintenance, keeping your operating costs under control.

The Pozitive Advantage

|

30+ Years of Expertise |

Unrivalled Selection |

Tailored Solutions |

Competitive Pricing & Fast Delivery |

At Pozitive, we know what makes a Mimaki print and cut machine run at its best because we’ve spent decades helping Aussie print businesses do just that. Whether you’re launching a new setup or scaling your production, we’ll guide you to the right model for your workflow.

- Built Around Your Workflow: From vibrant window decals to full vehicle wraps, we’ll help match the right Mimaki model to your needs, whether you're scaling up or just getting started.

- Support That Goes Further: Need guidance with RIP software, colour profiles or cut registration? We’ve got your back long after setup. Our team is local, practical, and easy to reach.

- In Stock and Ready to Ship: No long lead times or mystery costs. We hold popular Mimaki systems locally, priced competitively and delivered quickly, so you can hit the ground printing.

Browse Our Selection and Contact Us Today

A Mimaki print and cut machine is more than just a printer. It’s a complete solution for fast, flexible, professional-grade production. If you’re ready to cut setup time, reduce handling, and deliver flawless results in every job, we’re here to help.

Browse our Mimaki range today or contact us for honest advice and a solution that suits your space, budget and business goals.